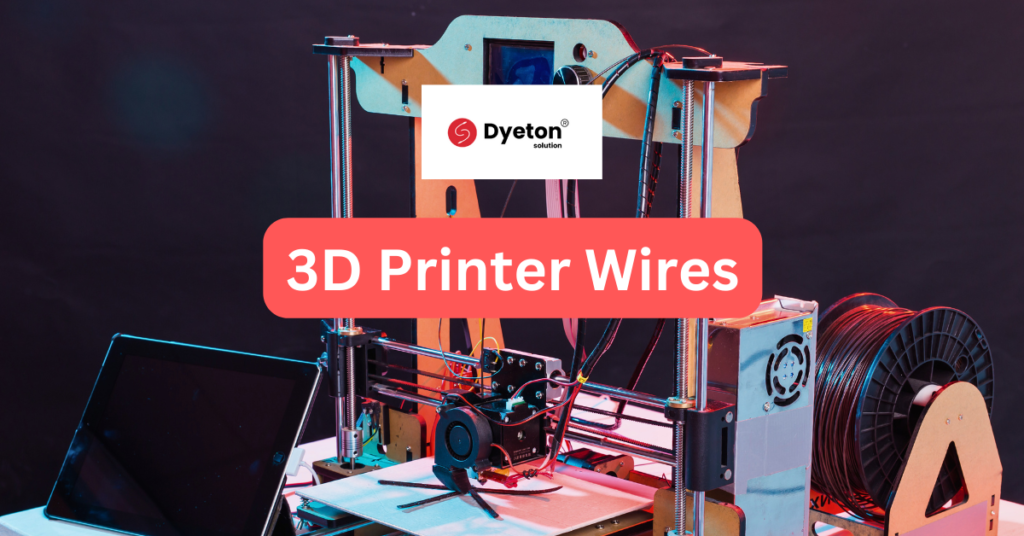

The industrial revolution transformed the production line for the first time, and it has evolved tremendously ever since. 3D printers have now become game-changers and set the pace of manufacturing. In a tech-driven world, there is a reason why 3D printers are referred to as “rapid prototypes”. 3D printers cater to the needs of the growing population in a fast and efficient way. This wouldn’t have been possible if it wasn’t for high-quality 3D printer wires. 3D printers have numerous advantages; Dyeton has briefed them for you.

3rd Printer Wires

1. Sustainability

One of the best aspects of 3D printing is it requires less outsourcing of material. This helps in reducing the carbon footprint. Additionally, investing in good quality 3D printer wires can go a long way in reducing waste.

2. Accessibility

3D printers are slowly replacing traditional manufacturing systems as they are accessible to a broad section of the population. However, the whole question of the democratization of manufacturing with these devices remains unanswered.

3. Flexibility and Quality

With 3D printing, you can create anything within its build volume. Unlike a traditional setup, these systems work with little to no change in the machinery. It comprises multiple materials that enhance the mix and match of textures and colours. The dynamics of 3D printer wires have a significant role in improving the flexibility of these devices.

4. Risk Control

Because of the consistency and quality, 3D printers can mitigate the risk of faulty production. The dynamic technology in these devices thoroughly verifies the product prototype before starting, thereby allowing better risk control.

Now that you have understood the benefits, let’s dig into the wiring of 3D printers. These systems are predominantly pre-wired. However, you might realize that some wires are too short while organizing the electrical components. The only practical solution is getting extensions.

5. The gauge of the wires

While looking for extensions, you need to purchase 3D printer wires with a thicker gauge. It improves the power supply and thereby reduces the risk of heating up.

6. Insulation

Sheathing is another necessity when it comes to wires. Silicon insulation is preferred in 3D printing for its high-temperature resistance. Moreover, different colours in wiring help identify and ease the process of connecting to terminals.

7. Wire Extension

The best way to connect wires is through Soldering. If you don’t own a soldering device, there is a wide range of pluggable connectors in the market for you to check out.

8. Connection to motherboards

Screw terminals help connect the power supply, heated bed and other high-current components to the motherboard. Molex connectors are handy to connect stepper motors and limit switches.

Conclusion

3D printers have given momentum to life by bringing zillion ideas into reality in a blink. Design and manufacturing are slowly inclining towards popular culture. With so many advantages, installing a 3D printer is a no-brainer. But keep in mind that as much as the devices are essential, 3D printer wires are also crucial for hassle-free production. The dynamics of 3D printer wires work on the lines of polarity. Take the necessary precautions to avoid heating up.