Electrical cables play a crucial role in our everyday lives, providing power and connectivity to various devices and systems. However, it is vital to ensure the quality of electric cable to maintain safety and efficiency. In this blog, we will discuss how to check quality of electric cable.

Indian electrical standards

Before proceeding to the quality checks, it is essential to be familiar with the electrical standards of the power supply and the appliances used. In India, the Bureau of Indian Standards (BIS) provides certification for electrical cables under the Indian Standard (IS) code, which is usually displayed on the packaging of good quality cables.

Visual Inspection

Visual inspection is the first step in assessing the quality of electrical cables. While inspecting the cables, pay close attention to the following factors:

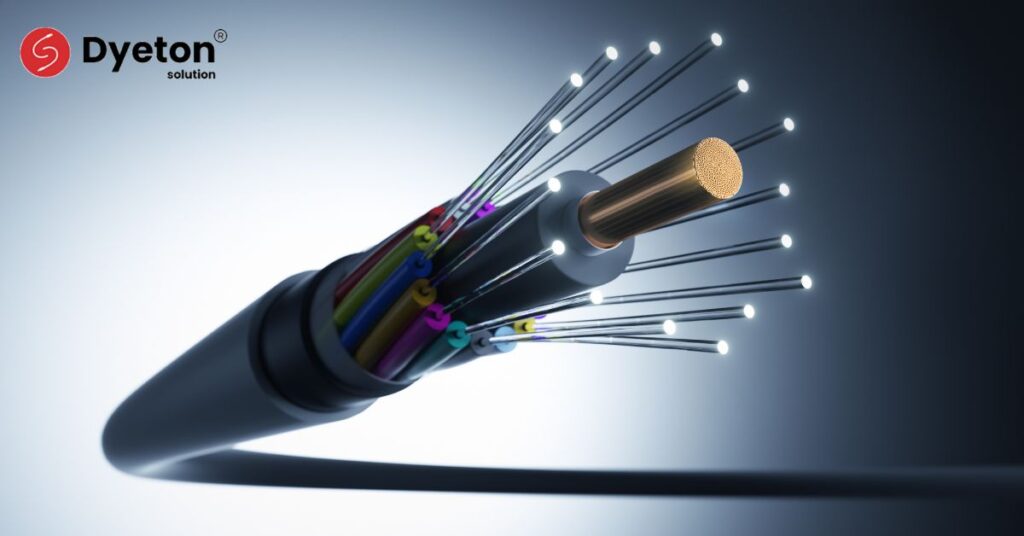

1. Insulation Quality

Examine the insulation material covering the conductor. It should be free from cuts, abrasions or any sign of damage. High-quality insulation ensures proper insulation resistance and protects against electrical faults.

2. Uniform thickness

Feel along the length of the cable to check for consistent insulation thickness. Inconsistent insulation thickness can indicate manufacturing defects or substandard quality.

3. Colour and markings

The cable’s colour and markings should comply with the standard coding of different types of cables. Ensure that the markings indicate the manufacturer’s name, trademark, cable size, and the ISI certification mark.

4. Cable flexibility

Bend and twist the cable gently to check its flexibility. Good quality cables should be flexible and resistant to cracking or breaking.

Electrical properties inspection

Beyond visual inspection, it is crucial to evaluate the electrical properties of the cable. While more advanced testing requires specialized equipment, some basic tests can be conducted using simple tools

1. Continuity test

Use a multimeter to check the continuity of the conductor inside the cable. This is done to ensure that there is no open circuit or short circuit that could cause power disruptions or electrical hazards.

2. Insulation resistance test

This test measures the resistance between the conductor and the insulation. Higher insulation resistance indicates better quality. An insulation resistance tester, commonly known as a megger, is used for this purpose.

3. Voltage drop test

Measure the voltage drop across the cable when it carries a specific current. Excessive voltage drops can lead to power loss and ineffective operation of connected devices. But, it should be kept in mind that voltage drop varies with the length and current capacity of the cable.

Buying tips for Good quality electrical cables

To ensure you purchase good quality electrical cables, consider the following tips:

1. Reliable brands

Opt for electrical cables from reputable manufacturers like Dyeton, who are known for their adherence to quality standards. Research and choose brands that have a good reputation and positive customer reviews.

2. Certification

Seek cables that have the ISI certification mark, which indicates compliance with Indian standards. BIS-certified cables undergo many rigorous testing processes.

3. Gauge selection

Determine the appropriate gauge selection for your intended application. You can refer to our previous blog for the gauge selection chart. Using an undersized cable can lead to overheating and electrical hazards, while an oversized cable can be costly and inefficient.

4. Copper purity

It is best to go for high-quality copper conductors, as they offer better conductivity and durability. Ensure that the conductor is made of pure copper instead of copper-coated aluminium (CCA), which is of inferior quality.

5. Application-specific cables

Consider the specific requirements of your application. Some cables are designed for specific purposes like underground wiring, outdoor installations, or high-temperature environments. Choose cables suitable for your intended use.

Conclusion

Checking the quality of electrical cables before buying or usage is essential to maintain safe and reliable electrical equipment. Visit Dyteon Solution to explore a variety of high-quality electrical cables for every electrical application.